![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:150KG-800KG/H

Application scope:TOFFEE CANDY

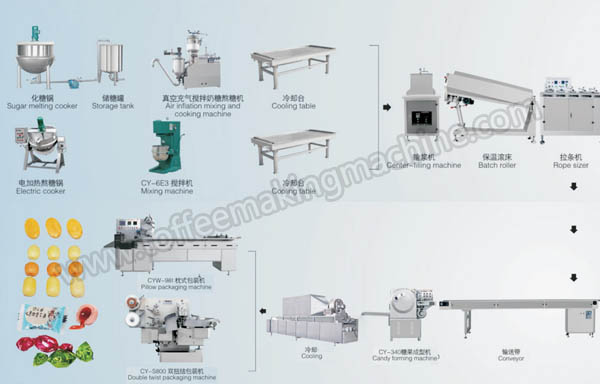

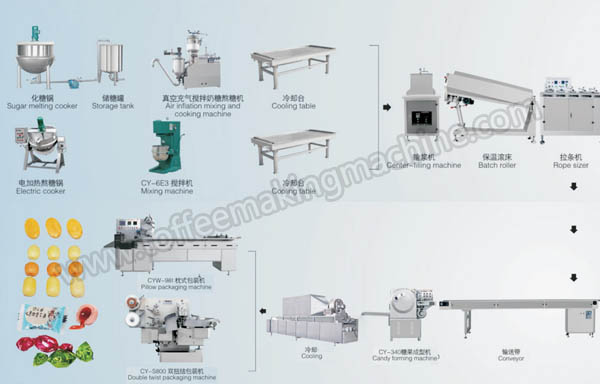

Product introduction: Technological process of Automatic Die-Formed Toffee Candy Making Equipment,Storage tank,Air inflation mixing and cooking machine,Cooling table,Center filling machine,Batch roller,Rope sizer,Conveyor,Candy forming machine,Cooling sifter,packaging machine

Automatic Die-Formed Toffee Candy Making Equipment

Automatic Die-Formed Toffee Making Equipment

Features of this production line:

1 PLC automatic programming control sugar boiling temperature, time, pouring temperature and pouring speed;

2 9.7 "large LED touch screen display is easier to operate;

3.The production capacity can be from 150 kg to 450 kg per hour;

4 Frequency conversion speed control sugar liquid flow;

5. Complete quantitative filling and mixing of flavor, pigment and acid on line;

6 Conveyor chain belt, cooling system, double demoulding mechanism to ensure demoulding;

7.The whole production line is manufactured according to the standard, in line with the hygiene requirements of food GMP.

Technological process of Automatic Die-Formed Toffee Candy Making Equipment

Sugar melting cooker(Electric cooker)-Storage tank-Air inflation mixing and cooking machine(mixing machine)-Cooling table-Center filling machine-Batch roller-Rope sizer-Conveyor-Candy forming machine-Cooling sifter-packaging machine

Main component equipment of Toffee Candy Making Equipment

Air inflation mixing and cooking machine

Purpose and features:

Made of stainless steel, the unit realizes heating, concentration, rinsing, mixing and blending of traditional aerated candies through reasonable mechanical, electrical, penumatic and instrumental configuration. It is a key machine for boiling of aerated candies. It is provided with computer PLC automatic control device and touch screen operation. The vacuum boiling, aerating and mixing can be carried out automatically and alternately, so as to carry out high aerating or low aerating boiling of syrup. According to the need, it can also be additionally equipped with boiling pot for the addition of condensed milk or other auxiliary materials.

The machine has relatively high control precision, so the syrup boiled by this machine has very good quality. The machine is suitable for aerating boiling of such products as creamy candies, nougats, fruit candies, spun sugar and candy bar core materials.

Technical Parameters:

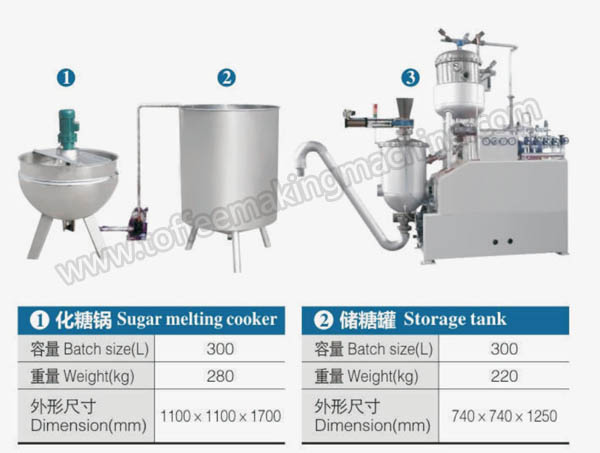

1. Sugae melting cooker

a) Batch size: 300L

b) Weight: 280kg

c) Dimension: 1100*1100*1700mm

2. Storage tank

a) Batch size: 300L

b) Weight: 220kg

c) Dimension: 740*740*1250mm

3. Air inflation mixing and cooking machine

a) Model: CY-300

b) Capacity: 300kg/h

c) Steam pressure: 0.7mpa

d) Steam consumption: 160kg/h

e) Compressed air pressure: 0.6mpa

f) Compressed air consumption: <0.25m³/min

g) Vacuum pressure: -0.06mpa

h) Vacuum pump power: 4kw

i) Main motor power: 17kw

j) Aerating pressure: <0.3mpa

k) Dimension: 2500*1500*3200mm

l) Machine weight: 1500kg

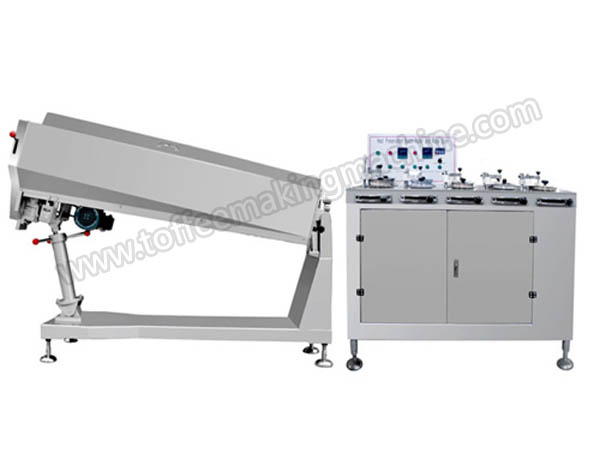

Heat preservation batch roller and rope sizer

Purpose and Features:

It is suitable for heat insulation and pulling of sugar pastes.

It has such features as simple operation, labor saving and high efficiency.

Multi function candy forming machine

Purpose

It is suitable for production of hard candies, gaining creamy candies, toffees and filled candies, as well as production of cushions (candy shapes varying according to customer requirements), such as: spherical, oblate, oval and other irregular shapes.

Feature

Punching and forming, stable running, high output

Technical parameters

Production capacity: w250kg/h

Total power: 2.4kw

Weight: 800kg

Dimension: 2000 x 1100 x1300mm

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemapCandy making machinecandy production lineToffee production lineToffee making machineGummy production linePopping boba production line