![]()

Adr :industrial zone, shanghai

Phone : +86 18221614363

Email : candymachinery@qq.com

Tel : +86 18221614363

processing capacity:150KG-800KG/H

Application scope:TOFFEE

Product introduction: Flow chart of Chain forming Toffee Candy making equipment,Toffee candy cooking machine Cooling drum Candy pulling machine Batch roller Candy rope sizer Chain forming machine Candy rope sizer Candy cooling tunnel

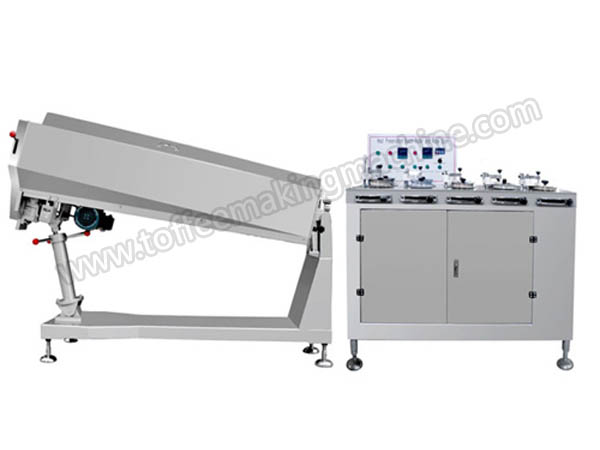

Automatic Chain Die Forming Toffee Making Equipment

Advantages of Toffee making equipment

The chain stamping speed is fast, the product quality is good, and the sandwich content can reach more than 20%

Continuous cooling drum with rotor cooking machine, cooking pressure up to 8kg, good product quality

Change the chain stamping die without pressure in five minutes

With high output, it can be used with different cooking equipment to produce various stamping products

Flow chart of Chain forming Toffee Candy making equipment

Toffee candy cooking machine-Cooling drum-Candy pulling machine-Batch roller-Candy rope sizer-Chain forming machine-Candy rope sizer-Candy cooling tunnel

Main equipment of Chain forming Toffee Candy making equipment

Toffee Candy Cooking Machine

Model :G-300

Capacity:300kg/batch

Power:6kw

Size(L*W*H) :1340*1340*1940mm

Weight :900kg

Toffee Candy Cooking Machine has the characteristics of strong flexibility and simple structure. It is suitable for cooking caramel, toffee, syrup, sugar chops, etc. The machine is controlled by an economical and efficient micro-processing system, which not only makes it easier to operate the machine, but also can simultaneously smelt sugar in a container. The contact part of the machine and the syrup is all made of stainless steel.

Cooling drum

Output :300-600kg/h

Drum diameter :1200-1500mm

Drum speed :2.4r/min

Drum width :710mm

Power :1.5-3kw

Size :2150*1850*1750mm

After passing through the toffee sugar boiling machine, the sugar liquid enters the cooling roller for cooling treatment

Candy Pulling Machine

Capacity:800kg/h

Power :18kw

Size (L*W*H) :2980*1680*2330mm

Weight :2200kg

Candy Pulling machine can meet the various requirements of whitening sugar making process and can be used for high-temperature cooking and low-temperature cooking of various syrups. The equipment can pull syrups with higher requirements on structure and texture, and the syrup drawing time and mechanical pull arm speed can be adjusted according to needs.

Batch Roller

The heat preservation rolling bed is composed of a transmission box, 4 rollers, a lifter, a bracket, and a regulator. It is used for rolling and squeezing the massecuite to make it soft and even into strips, suitable for processing by lower-level homogenizing machines.

Candy Rope Sizer

Maximum speed:100m/min

Power:3.5kw

Size(L*W*H):1400mm*700mm*1200mm

Weight:400kgs

rope sizer usually work together with batch roller and die forming machine. The sugar mass is delivered by batch roller and fed to rope sizer to process by five pairs of sizing roller unitll reaching the target size. Then processed sugar mass is fed to the following die forming machine. All sizing rollers have heater under them to keep sugar mass’s temperature during processing.

Chain Forming Machine

Capacity:80m/min

Frequency :50HZ

Power :7KW

Weight :1000kg

chain stamping machine is a new generation of stamping candy equipment, which can be used to produce hard candy and chewing soft candy with or without filling. Sugar chips and dust are easily collected in the space below the molding part. Significantly reduce the wear of parts in production. Compared with the disc stamping forming method, the products of the chain forming machine have the characteristics of higher filling volume and easier demolding of soft candy.

All rights reserved:ZHI YAN CANDY MACHINERY Co.,Ltd SitemapSitemapCandy making machinecandy production lineToffee production lineToffee making machineGummy production linePopping boba production line