Toffee making machine manufacturing process is divided into die-formed toffee production line and depositing toffee candy production line and Extrusion toffee making equipment

1.Die-formed Fully automatic Toffee Production Line

die forming toffee production line(toffee making machine)

Features of toffee production line:

-PLC automatic programming control sugar boiling temperature, time, pouring temperature and pouring speed;

-9.7 "large LED touch screen display is easier to operate;

-The production capacity can be from 150 kg to 450 kg per hour;

-Frequency conversion speed control sugar liquid flow;

-Complete quantitative filling and mixing of flavor, pigment and acid on line;

-Conveyor chain belt, cooling system, double demoulding mechanism to ensure demoulding;

-The whole production line is manufactured according to the standard, in line with the hygiene requirements of food GMP.

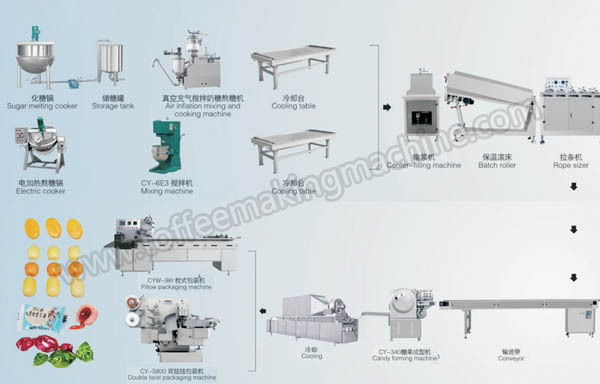

1.Technological process of Filled/unfilled toffee candy production line

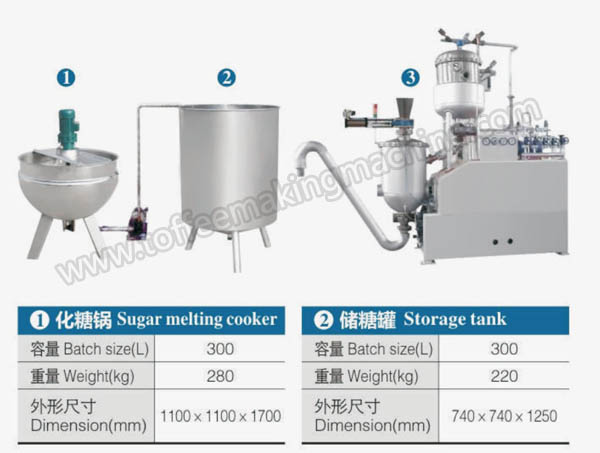

Sugar melting cooker(Electric cooker)-Storage tank-Air inflation mixing and cooking machine(mixing machine)-Cooling table-Center filling machine-Batch roller-Rope sizer-Conveyor-Candy forming machine-Cooling sifter-packaging machine

Air inflation mixing and cooking machine

Purpose and features:

Made of stainless steel, the unit realizes heating, concentration, rinsing, mixing and blending of traditional aerated candies through reasonable mechanical, electrical, penumatic and instrumental configuration. It is a key machine for boiling of aerated candies. It is provided with computer PLC automatic control device and touch screen operation. The vacuum boiling, aerating and mixing can be carried out automatically and alternately, so as to carry out high aerating or low aerating boiling of syrup. According to the need, it can also be additionally equipped with boiling pot for the addition of condensed milk or other auxiliary materials.

The machine has relatively high control precision, so the syrup boiled by this machine has very good quality. The machine is suitable for aerating boiling of such products as creamy candies, nougats, fruit candies, spun sugar and candy bar core materials.

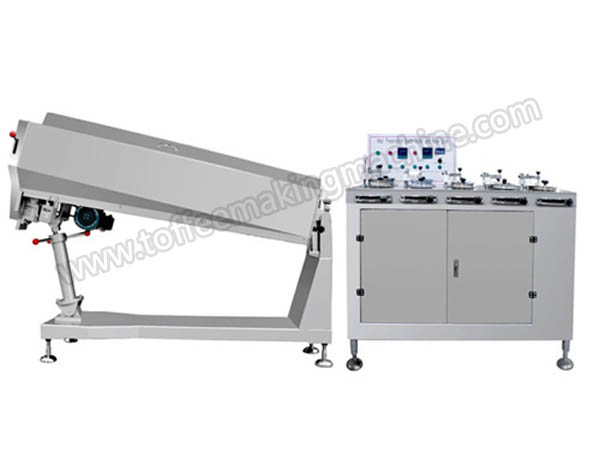

Heat preservation batch roller and rope sizer

Purpose and Features:

It is suitable for heat insulation and pulling of sugar pastes.

It has such features as simple operation, labor saving and high efficiency.

Multi function toffee candy forming machine

It is suitable for production of hard candies, gaining creamy candies, toffees and filled candies, as well as production of cushions (candy shapes varying according to customer requirements), such as: spherical, oblate, oval and other irregular shapes.

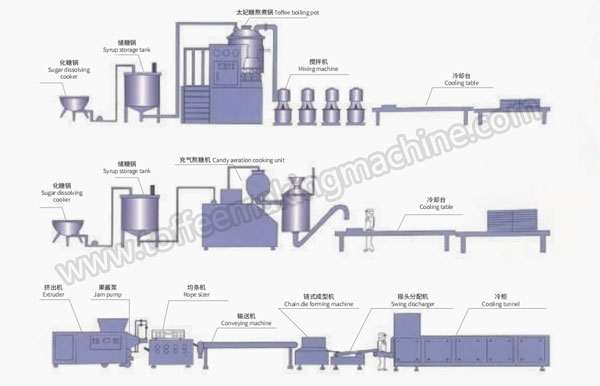

2.Fully automatic Chain die forming toffee making machine

Fully automatic Chain die forming toffee making machine

Flow chart of Chain forming Toffee making machine (toffee making equipment)

Toffee candy cooking machine-Cooling drum-Candy pulling machine-Batch roller-Candy rope sizer-Chain forming machine-Candy rope sizer-Candy cooling tunnel

Advantages of Toffee production line

The chain stamping speed is fast, the product quality is good, and the sandwich content can reach more than 20%

Continuous cooling drum with rotor cooking machine, cooking pressure up to 8kg, good product quality

Change the chain stamping die without pressure in five minutes

With high output, it can be used with different cooking equipment to produce various stamping products

Main equipment of Chain Die Forming Toffee Candy Production Line

Toffee Candy Cooking Machine

Toffee Candy Cooking Machine has the characteristics of strong flexibility and simple structure. It is suitable for cooking caramel, toffee, syrup, sugar chops, etc. The machine is controlled by an economical and efficient micro-processing system, which not only makes it easier to operate the machine, but also can simultaneously smelt sugar in a container. The contact part of the machine and the syrup is all made of stainless steel.

Cooling drum

After passing through the toffee sugar boiling machine, the sugar liquid enters the cooling roller for cooling treatment

Chain Forming Machine

chain stamping machine is a new generation of stamping candy equipment, which can be used to produce hard candy and chewing soft candy with or without filling. Sugar chips and dust are easily collected in the space below the molding part. Significantly reduce the wear of parts in production. Compared with the disc stamping forming method, the products of the chain forming machine have the characteristics of higher filling volume and easier demolding of soft candy.

3.Extruding forming Toffee candy production line

Extruding forming Toffee making equipment

central-filling Toffee candy producing line is one of the main products of ZY Machine. It was introduced and developed according to the demands of the customer that are tasty, functional, colorful, nutritional, etc,. This soft-milk production line can reach to the advanced technology in appearance and performance all over the world.

•Automatic control for alternated process of vacuum cooking and aeration/mixing;

•An unique design of aeration/mixing system guarantees a high quality product;

•The production capacity can reach to 300kg/h;

•Automatic process control synchronized with central-filling/extruding/rope sizing;

•Chain style die-forming for different shapes of candy;

•toffee candy,Soft candy, central-filled soft candy, eclair candy and etc., Can be made.

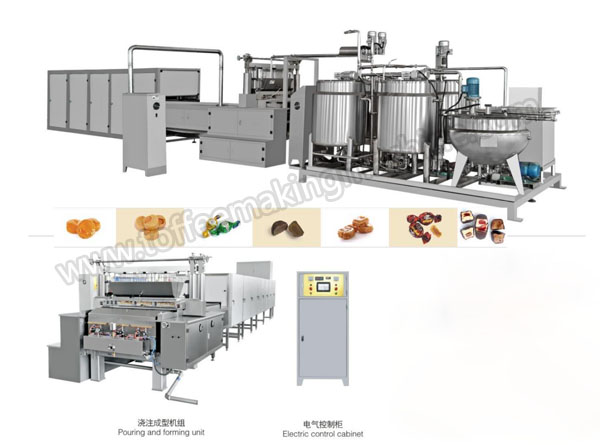

4.Automatic Depositing Toffee Candy production Line

Automatic Depositing Toffee Candy production Line

Toffee making equipment is an advanced and continuous plant for making different types of toffee candy. It is an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occu- pied.this depositing line consists of jacket dissolving cooker, gear pump, storage tank, special toffee cooker,discharging pump, color & flavor dosing system, color & flavor mixer, depositor, cooling tunnel, electric control cabinet, etc.

Flow chart of Automatic Depositing Toffee Candy production Line

Dissolving cooker-Syrup storage tank- Toffee cooker-Depositor-Cooling tunnel

Toffee cooking machine

The toffee cooking machine is designed to cook a variety of candies, including toffee, eclairs, and caramel. Candy is heated via a steam stirring process to effectively prevent charring.

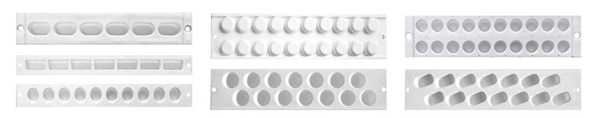

Mold

The production line manufactures candies in different shapes using different molds. We will design molds according to customer needs.

Depositing machine

The depositing machine is composed of depositing head, mold, and refrigerated cooler with the depositing head equipped with a double hopper. By replacing the stamping board and nozzle, this equipment is used to manufacture filled toffee candies. Temperature, depositing speed and other parameters are PLC controlled, with parameters easily displayed and set on the touchscreen. Syrup flow is precisely controlled using the frequency control system to ensure a stable sugar paste quality.

Start Your Perfect Toffee and Milk Candy Production As a world-class candy production line manufacturer, We can perfectly provide the production line and production advice required for Toffee production. If you have any needs, you can visit our Toffee production line website to get the latest product consultation and complete solutions. Contact us immediately to communicate with our professional technical team.